1087

According to a press release sent to Meat.Milk., Mondi, a global leader in sustainable packaging and paper, is collaborating with advanced biomaterial engineers from traceless to develop a new coating solution based on agricultural industry by-products.

This innovative bio-circular coating solution is the first of its kind and will be able to replace the traditionally used plastic coating.

There is an increasing demand for plastic alternatives in packaging solutions, and this new coating will directly address that demand:

- Made from renewable plant-based materials, specifically residues from the agricultural industry, it eliminates the need for fossil raw materials.

- Life cycle assessments of traceless have shown that providing traceless® material to the market leads to overall greenhouse gas savings of 76% from supply to disposal when the material is used as a substitute for virgin PET.

- When considering only the production and disposal phases, these savings rise to 95%. The material is also certified as home compostable by DIN CERTCO according to NF T51-800.

The joint work of Mondi and traceless on this product began in 2021 and brought together world-leading expertise: Mondi's knowledge in paper coating and packaging solutions and traceless’s expertise in polymer-based natural material solutions.

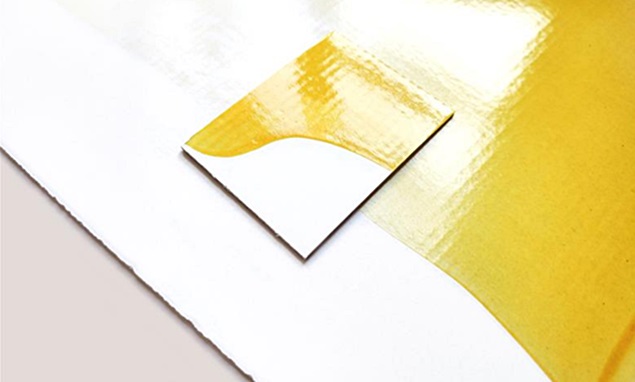

Coating granules are produced in the traceless pilot facility and applied to Mondi kraft paper at Mondi's research and development center for further testing of the coated paper in the company's laboratories. Subsequent industrial-scale production will take place in a designated plant in Hamburg.

Various products require different barriers in their packaging, and the coated kraft paper solution is thoroughly tested for different packaging purposes to ensure it can be used across various end markets: in-depth tests have confirmed that kraft paper coated with traceless® can withstand water, oxygen, and grease while also providing good printability for different customers.

At the same time, the goal is to develop a solution that is also recyclable in existing recycling streams across Europe.

Currently, the properties of the bio-based coating are being further optimized, adjusting the solution to make it suitable for different packaging applications for various end markets such as e-commerce, frozen foods, fatty and non-fatty foods.

The goal is to achieve a packaging solution that can be scaled for a range of different industries and that significantly reduces greenhouse gas emissions throughout the packaging life cycle.

Marko Schuster, COO Functional Paper and Films at Mondi, says: “We are always looking at the next steps in creating truly circular packaging, following the demands of our customers as well as our own innovative spirit. This is a fantastic example of how we can combine our research and development strengths to stay ahead in the sustainable packaging game, contributing to a circular economy.”

Anne Lamp, CEO and co-founder of traceless, adds:

“Our mission is to make pollution and waste a thing of the past by using materials that have a positive impact. The journey so far has been exciting and insightful, teaching us valuable lessons to ensure our packaging provides excellent protection. Working with Mondi - its team, machines, products, and processes - we are adapting our existing expertise in innovative biomaterials to reduce plastic barrier coatings in packaging. The goal is to create a product truly fit for purpose that works for a wide range of applications and industries.” (Photo: Mondi)