1428

Sartorom to Participate in the 14th Edition of the International Meat.Milk. Expo-Conference

Sartorom will proudly participate in the 14th edition of the Meat.Milk. International Expo-Conference, a premier event for Romania’s meat and dairy sectors, scheduled to take place on May 26–27 at the Alpin Hotel in Poiana Brașov.

Competitive Advantages: Optimizing Production and Boosting Profitability with Sartorom Solutions

In today’s competitive business environment—where efficiency and waste reduction are key to success—Sartorom, with over 30 years of experience, stands out as a leader in providing state-of-the-art technological equipment.

The company delivers innovative and reliable solutions across a wide range of industries, including the food sector, helping businesses overcome challenges and ensure high-performance production processes.

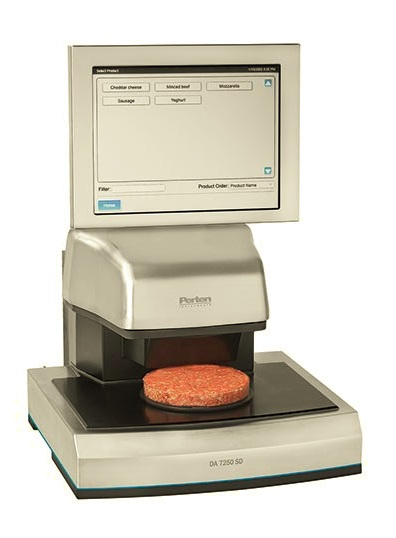

Maximizing Performance in the Food Industry with the DA 7250 SD

At the event, Sartorom will highlight the capabilities of the DA 7250 SD, an advanced instrument designed for real-time process optimization in the food industry. With rapid and accurate analysis of raw materials and finished products, the DA 7250 SD supports producers in maximizing yield, improving product consistency, and reducing operational costs.

This solution is particularly valuable in the meat and dairy industries, where quality control and process efficiency are essential to maintaining competitiveness and profitability.

Precision and Speed in Meat Processing with DA 7250 SD

For meat processors and producers of meat-based products, accurate monitoring of nutritional parameters—such as moisture, protein, and fat—is a critical aspect of the manufacturing process.

Advanced NIR Technology for Rapid, Reliable Results

Near-Infrared (NIR) spectroscopy is widely recognized as one of the most effective methods for measuring these parameters. The DA 7250 SD from Sartorom leverages this advanced technology to deliver fast and highly accurate results.

One of the main challenges of previous technologies was the need for time-consuming sample preparation—such as using specific cups and cleaning between analyses. The DA 7250 SD overcomes this with an innovative multi-component analysis method that delivers results in just 6 seconds, with no sample preparation required.

Clean, Simple, and Operator-Friendly

The analysis is performed directly in an open container, and the use of disposable Petri dishes eliminates the need for cleaning between samples, reducing operator error. The device’s hygienic design and easy-to-clean surfaces ensure fast and efficient maintenance.

Accurate Analysis of Moisture, Protein, and Fat

The DA 7250 SD provides precise and rapid measurements of moisture, protein, and fat in meat and meat products. It delivers exceptional accuracy even in samples with low water content (from 20%), and can reliably assess protein and fat concentrations across a broad range of raw and processed meat types.

Ekomilk Horizon MINI-LAB: The Fully Automated Milk Analysis Solution

Stay tuned—Sartorom also presents the Ekomilk Horizon MINI-LAB, a fully automated system for precise milk analysis, streamlining dairy testing and ensuring quality control in every batch.

Ekomilk Horizon MINI-LAB: Fully Automated Milk Testing for High-Throughput Labs

For dairy farmers, producers, and processors, Sartorom offers the Ekomilk Horizon MINI-LAB, a fully automated system designed to simplify and streamline the milk testing process. This advanced equipment automates sample preparation and analysis, delivering reliable results for key parameters, including the somatic cell count (SCC).

Optimized for High-Volume Laboratories

Ideal for large-scale laboratories, the Ekomilk Horizon MINI-LAB supports a continuous, fast, and efficient workflow, enabling simultaneous analysis of up to 49 samples.

The system includes two essential components:

- Ekomilk Horizon UNLIMITED A hybrid analyzer that uses ultrasonic and viscosity-based methods to measure SCC and other milk parameters. It features Wi-Fi connectivity, an integrated printer, and remote data transfer capabilities for seamless lab integration.

- Ekomilk-AMP Sample Feeder An automated sample feeder designed to handle up to 49 samples per tray, significantly improving lab throughput and operational efficiency.

Real-Time Monitoring and Smart Notifications

Test results are automatically transferred to the AMP platform, where they can be monitored in real time and analyzed through a smart notification system. This ensures fast feedback and alerts based on custom thresholds, supporting a reliable and efficient production process.

Powerful Benefits for the Food Industry

Sartorom delivers a competitive edge to companies in the food industry through its high-performance equipment.

These solutions help maximize efficiency, reduce losses, and enhance control over nutritional parameters, directly impacting profitability. Furthermore, the automation of analysis and workflow processes minimizes errors and saves time—two critical factors in modern food production.

Whatever the challenge, Sartorom provides smart, efficient solutions that ensure the quality and integrity of your production processes.