520

HEAT TREATMENT REQUIREMENTS

PASTEURIZATION OF MILK AND CREAM

PASTEURIZATION OF MILK IN VALVES AND CREAM IN PLATE PASTEURIZERS

CCP2 = CRITICAL CONTROL POINT = TEMPERATURE AND DURATION OF HEAT TREATMENT (example)

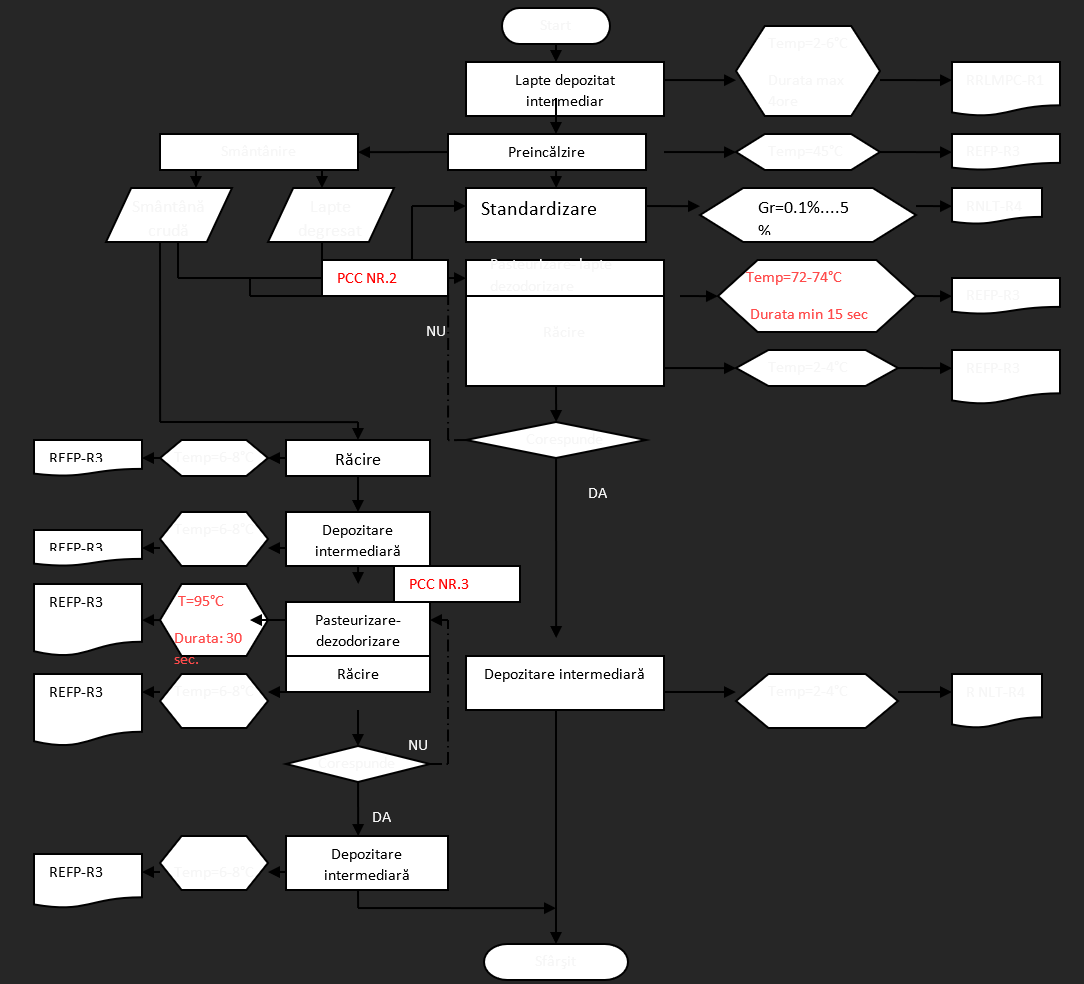

CRITICAL CONTROL POINT NO. 2

MILK PASTEURIZATION IN VAT

Hazard: Biological

Operating limit: Temperature 85 °C with holding time 30 minutes

Alert limit: Temperature 75 °C with holding time 30 seconds

Critical limit: Temperature 72 °C with holding time 30 seconds

CCP responsible: Pasteurization operator

Working method: Checking the pasteurization temperature and holding time

Frequency: Continuous temperature logger, with spot checks using a thermometer

Documentation: Electronic on PC and manual in the production logbook

Corrective actions: Phosphatase test in the laboratory. Re-pasteurization of milk.

In case of malfunction, the electrician is notified!

Responsibilities: Pasteurization operator, plant manager, electrician.

CRITICAL CONTROL POINT NO. 3

CREAM PASTEURIZATION IN PLATE PASTEURIZER

Hazard: Biological

Operating limit: Temperature 95 °C with holding time 30 seconds

Alert limit: Temperature 94 °C with holding time 30 seconds

Critical limit: Temperature 92 °C with holding time 30 seconds

CCP responsible: Pasteurization operator

Working method: Checking the pasteurization temperature and holding time

Frequency: Continuous temperature logger, with spot checks using a thermometer

Documentation: Electronic on PC and manual in the production logbook

Corrective actions: Test in the laboratory. Re-pasteurization of milk.

In case of malfunction, the electrician is notified!

Responsibilities: Pasteurization operator, plant manager, electrician.

APPLICABLE LEGISLATION http://data.europa.eu/eli/reg/2004/853/oj/ron (OJ L 139, 30.4.2004, p. 55) REGULATION (EC) No 853/2004 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 29 April 2004 laying down specific hygiene rules for food of animal origin

- Heat treatment of milk and dairy products When raw milk, colostrum, dairy products or colostrum-based products are subjected to heat treatment, food business operators must ensure compliance with the requirements laid down in Regulation (EC) No 852/2004, Annex II, Chapter XI. In particular, when using the following processes, compliance with the specifications listed must be ensured:

(a) Pasteurization is carried out by a treatment involving:

(i) a high temperature for a short time (at least 72 °C for 15 seconds); (ii) a lower temperature for a longer time (at least 63 °C for 30 minutes); or (iii) any other combination of time and temperature producing an equivalent effect, such that the products show, where appropriate, a negative reaction to the phosphatase test immediately after the treatment.

(b) Ultra-high temperature treatment (UHT) is carried out by a treatment:

(i) involving a continuous flow of heat at a very high temperature for a short time (not less than 135 °C, in combination with an appropriate holding period), so that no viable microorganisms or spores can develop in the treated product when it is kept in a closed and aseptic container at ambient temperature; and (ii) sufficient to ensure the microbiological stability of the product for 15 days at 30 °C in closed containers, or by any other method demonstrating that the appropriate heat treatment has been applied.

Where raw milk and colostrum are to be subjected to heat treatment, food business operators must:

(a) take into account procedures developed in accordance with HACCP principles, based on Regulation (EC) No 852/2004; (b) comply with the requirements laid down by the competent authority at the time of approval of establishments or when carrying out controls, in accordance with Regulation (EC) No 854/2004.

CRITERIA APPLICABLE TO RAW COW’S MILK Food business operators producing dairy products must apply procedures to ensure that, immediately after heat treatment and where the acceptable limit laid down in procedures based on HACCP principles is exceeded:

(a) raw cow’s milk used for the manufacture of dairy products has a germ count of less than 300,000/ml at 30 °C; (b) heat-treated cow’s milk used for the manufacture of dairy products has a germ count of less than 100,000/ml at 30 °C.

Where raw milk does not meet the criteria laid down in point 1, food business operators must inform the competent authority and take measures to remedy the situation.

OBSERVATIONS To claim, through marketing means, on labels or other media, that a “gentle pasteurization”, “mild” pasteurization, etc. is applied, when:

1.1. standard pasteurization treatments of milk at temperatures of 129–135 °C with holding times of 3–5 seconds are used, for ESL drinking milk with a shelf life of 3–4 weeks, using ESL pasteurization installations; 1.2. standard pasteurization treatments are used for milk intended for fresh products and cream, at a minimum of 65 °C for 30 minutes or 85–90 °C for at least 30 minutes (in vat), respectively 15 seconds (in plate pasteurizer);

1.1. standard pasteurization treatments of milk at temperatures of 129–135 °C with holding times of 3–5 seconds are used, for ESL drinking milk with a shelf life of 3–4 weeks, using ESL pasteurization installations; 1.2. standard pasteurization treatments are used for milk intended for fresh products and cream, at a minimum of 65 °C for 30 minutes or 85–90 °C for at least 30 minutes (in vat), respectively 15 seconds (in plate pasteurizer);

constitutes a misleading statement for the consumer.

P.S. For all the observations and texts above, there is extensive documentation based on specialized literature, established technological works, as well as photo and video materials referring to products for which marketing exaggerations are practiced, with the effect of indirectly discrediting competitors, a practice prohibited by current legislation (Law No. 363/2007 on combating unfair commercial practices of traders in relation to consumers and harmonizing regulations with European consumer protection legislation).

Dr. Eng. George Grecu